什么是单面板?

单面板的特点

结构简单

单层布线设计,制造工艺成熟稳定,生产过程易于控制,良率高。

成本效益高

材料用量少,工艺流程简单,生产成本低,特别适合大批量生产应用。

可靠性高

焊接点一目了然,维修和检测方便快捷,产品使用寿命长,可靠性高。

设计适用性强

适用于低密度、低复杂度电路设计,是入门级电子产品的最佳选择。

单面板常用材料

材料认证信息

材料类型

纸基/环氧玻璃布

阻燃等级

UL94 V-0/V-1/V-2

厚度范围

0.8mm - 3.2mm

Contact Us

Major Client

Single-sided Board Main Application:

单层布线设计,制造工艺成熟稳定,生产过程易于控制,良率高。

材料用量少,工艺流程简单,生产成本低,特别适合大批量生产应用。

焊接点一目了然,维修和检测方便快捷,产品使用寿命长,可靠性高。

适用于低密度、低复杂度电路设计,是入门级电子产品的最佳选择。

纸基/环氧玻璃布

UL94 V-0/V-1/V-2

0.8mm - 3.2mm

Computer Peripheral、Telecom

|

|

|

|

|||

HD-001 |

HD-002 |

HD-003 |

HD-004 |

|||

|

|

|

|

|||

HD-005 |

HD-006 |

HD-007 |

HD-008 |

|||

Single-sided PCB

|

SERIAL |

Item |

Technical Data |

|

|

1 |

Layers |

1 |

|

|

2 |

Cover plate type |

XPC、FR-1、FR-4、CEM-1、CEM-3 |

|

|

3 |

Copper thickness |

min |

70 um |

|

min |

18 um, 35 um |

||

|

4 |

Monthly capacity |

20,000 m2 |

|

|

5 |

Production and processing dimensions |

max |

460*610mm |

|

min |

100*150mm |

||

|

6 |

Finished board size |

max |

400*350mm |

|

min |

70*100mm |

||

|

7 |

Processing thickness |

max |

3.20mm |

|

min |

0.80mm |

||

|

8 |

Minimum line width |

0.20mm |

|

|

9 |

Minimum spacing |

0.20mm |

|

|

10 |

Minimum aperture |

Drilling |

0.30mm |

|

Punching |

0.60mm |

||

|

11 |

Aperture tolerance |

±0.05mm |

|

|

12 |

Hole Tolerance |

±0.05mm |

|

|

13 |

Overall Accuracy |

Milling shape |

±0.20mm |

|

Chong shape |

±0.10mm |

||

|

14 |

Minimum solder bridge |

0.15mm |

|

|

15 |

Hot song and bending |

Not MSD |

1.00% |

|

MSD |

0.75.% |

||

|

16 |

Insulation resistance |

1012ΩNormal |

|

|

17 |

Electric strength |

>1.3KV/mm |

|

|

18 |

Current resistance |

10A |

|

|

19 |

Anti-peel strength |

1.4N/mm |

|

|

20 |

Solder Mask Abrasion |

>4H |

|

|

21 |

Thermal Shock |

260℃ 10S |

|

|

22 |

Flame-retardant grades |

94V-0 |

|

|

23 |

Off test voltage |

50-300V |

|

|

24 |

Conductive Ink Resistance |

<200Ω |

|

|

25 |

Peel able Solder mask |

Easy Peeling |

|

|

26 |

Surface |

OSP FLUX, HASL, GOLD, etc |

|

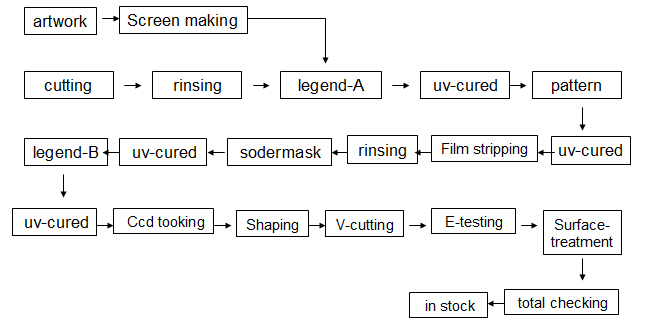

Technical Flow Chart

|