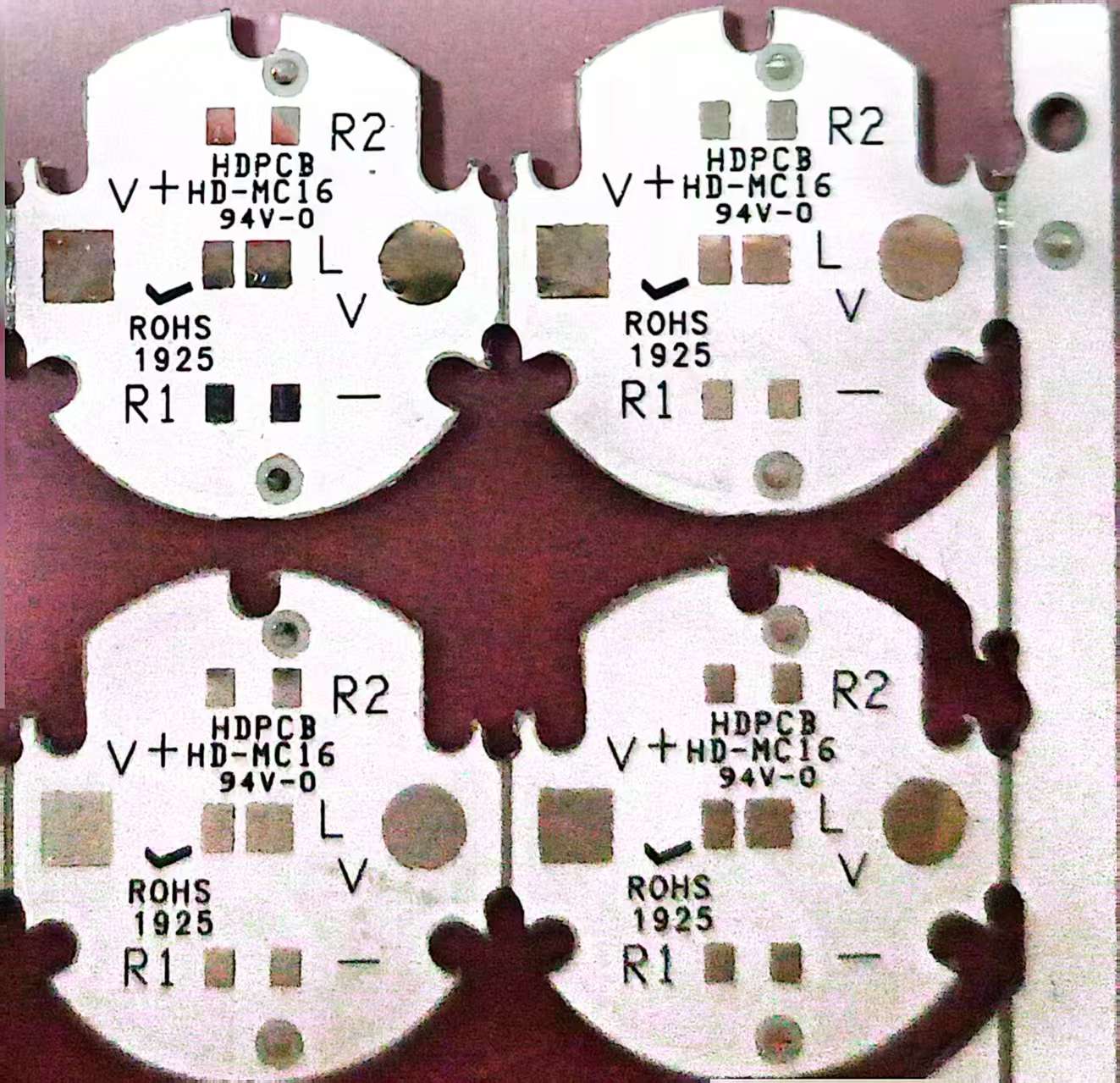

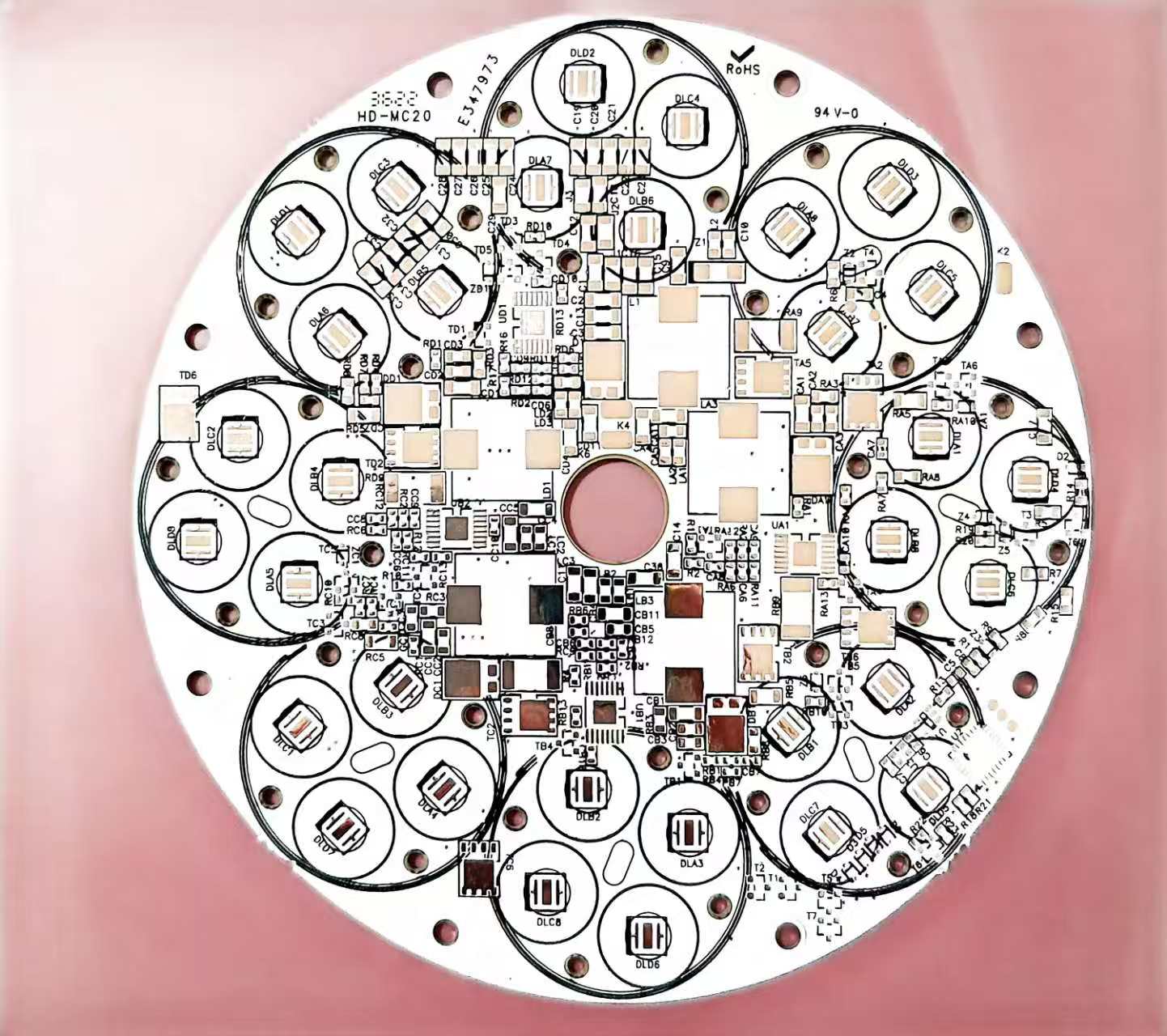

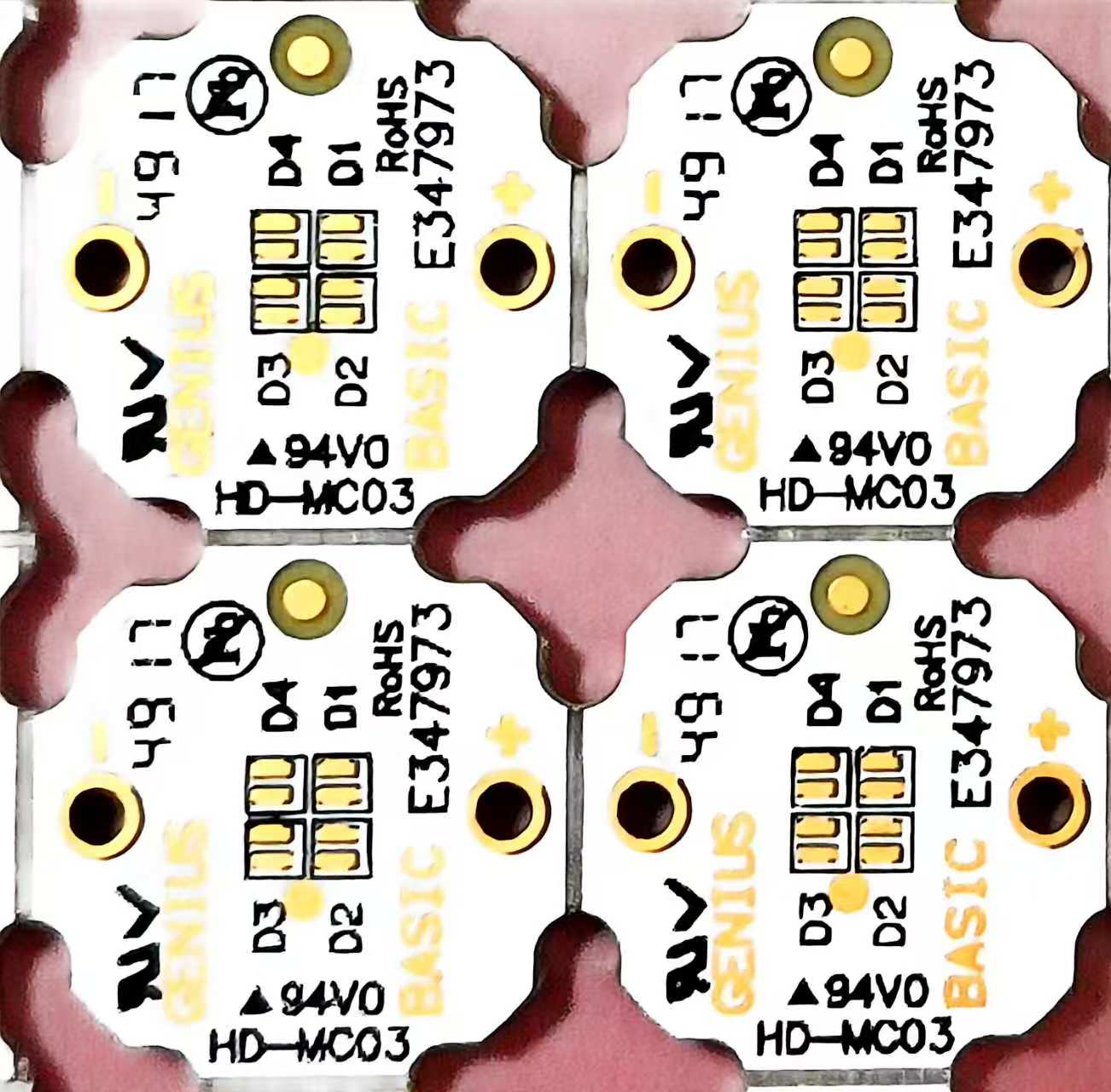

Description and

Application

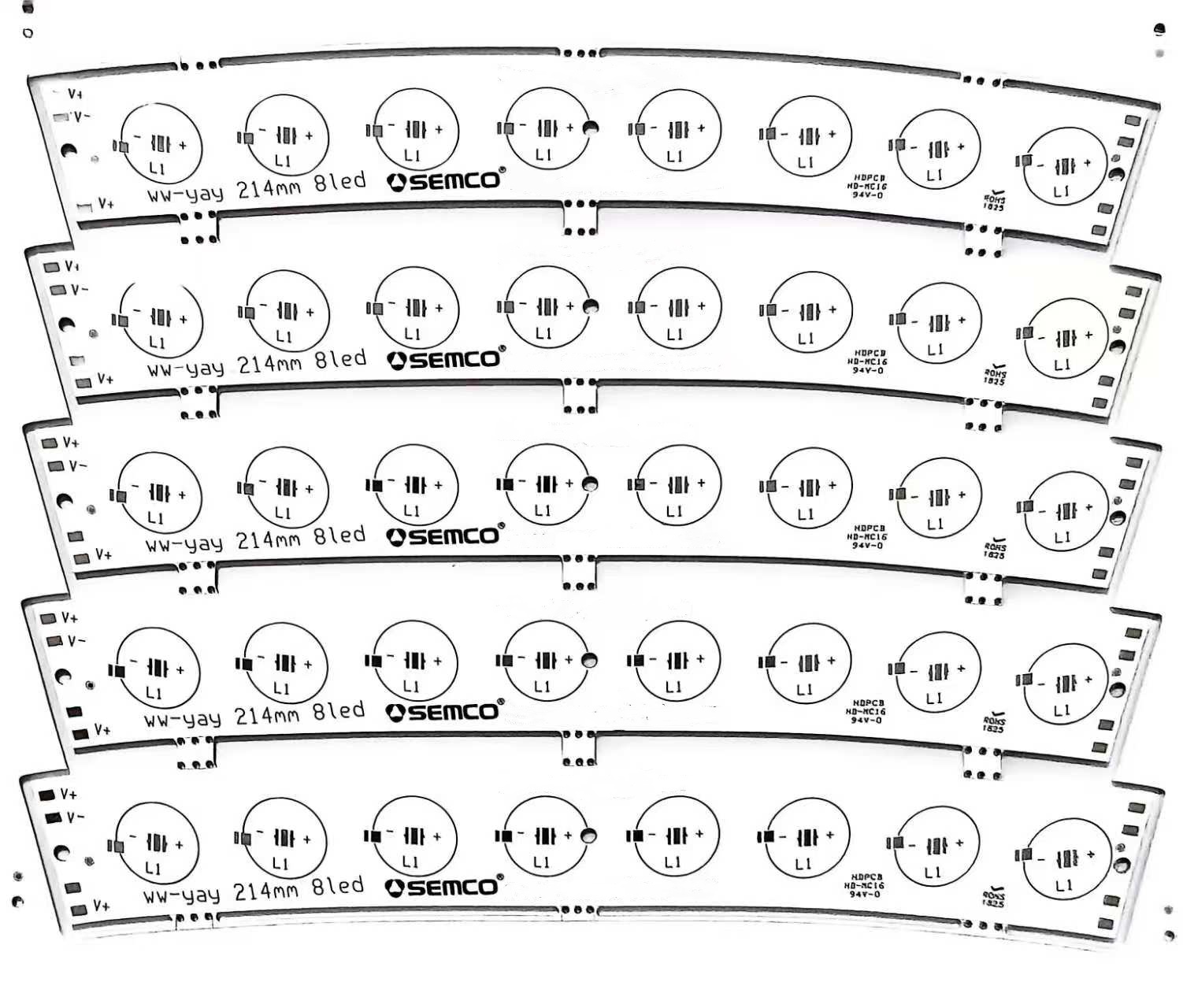

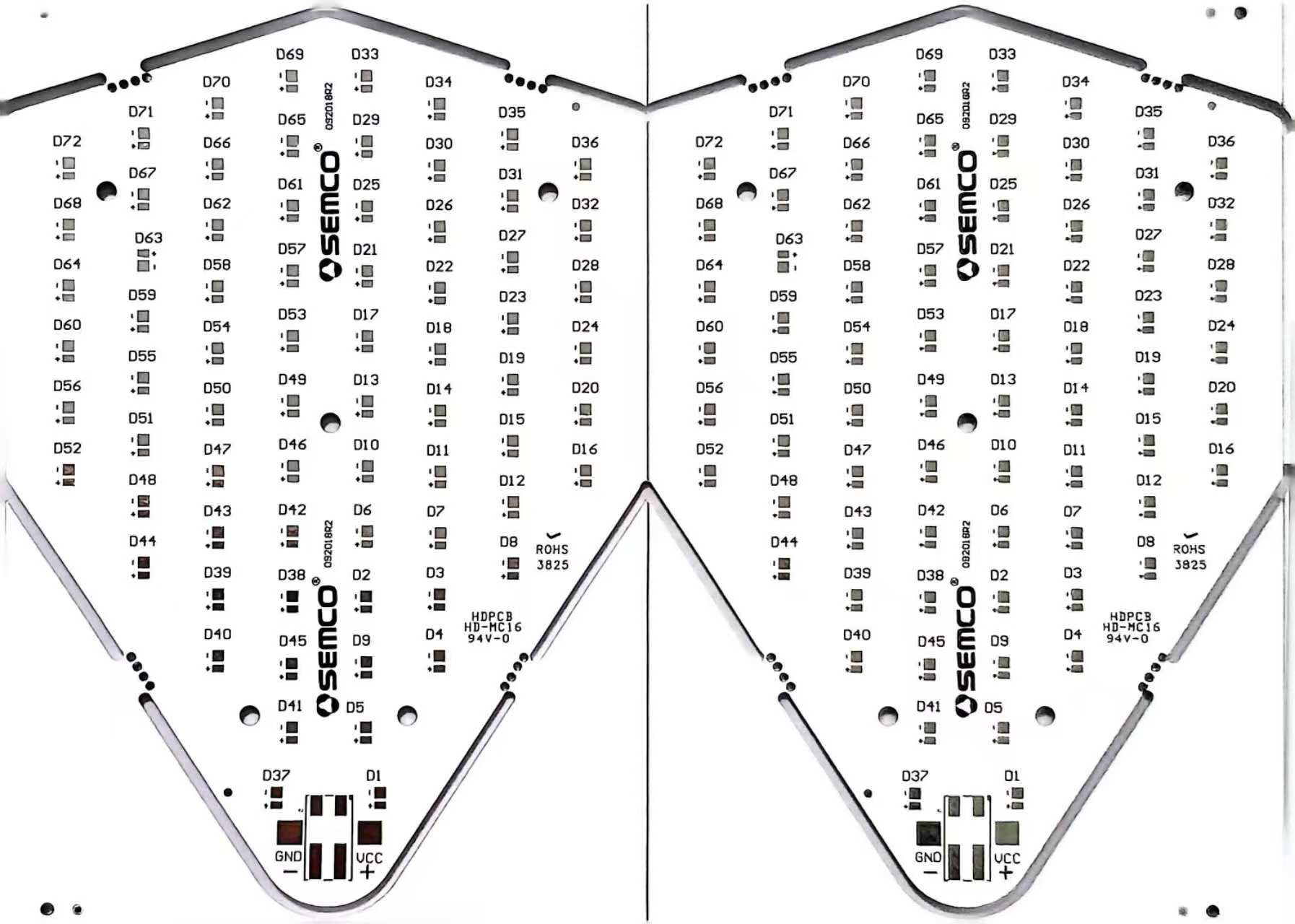

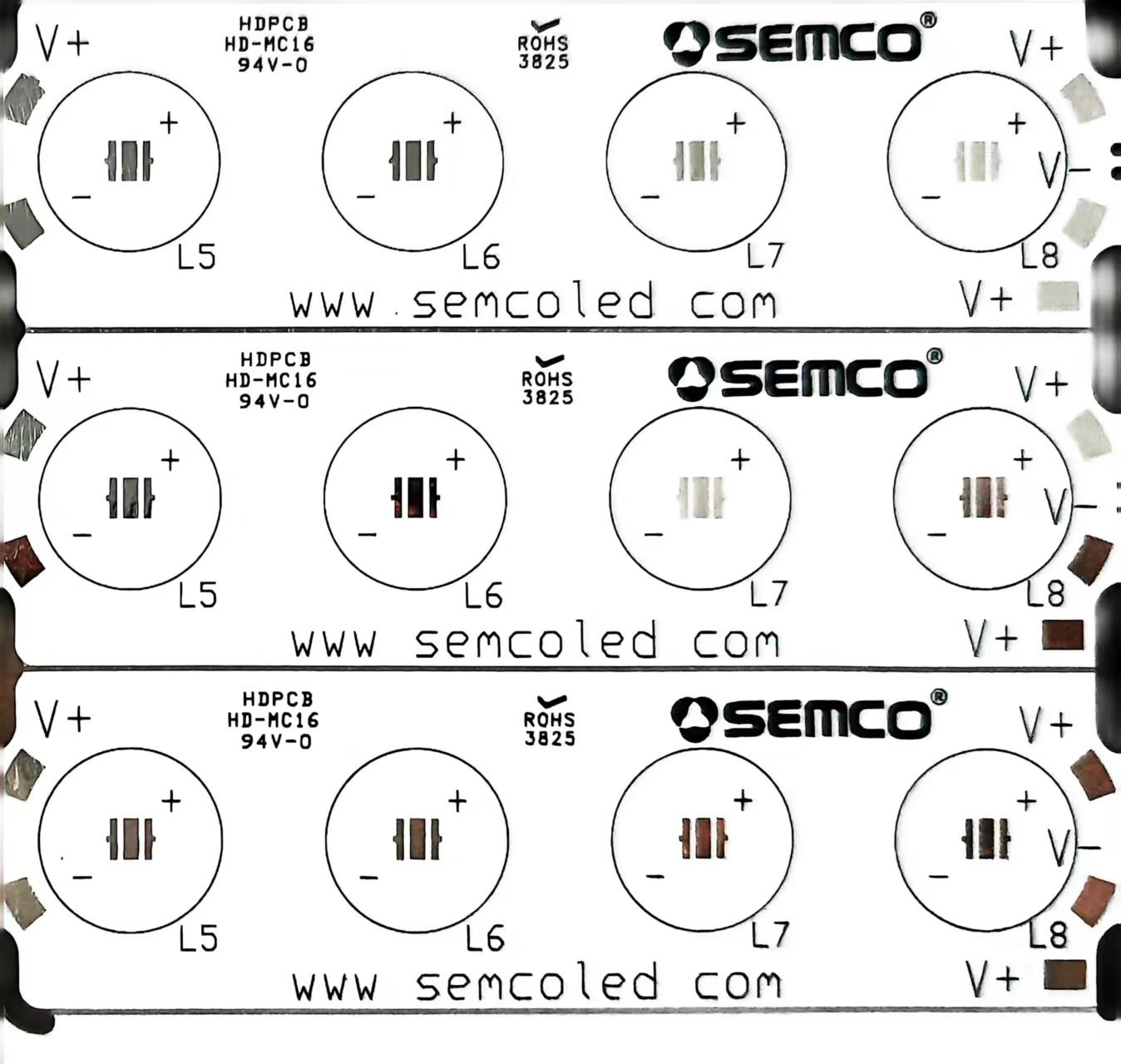

Aluminum base copper-clad

laminate have excellent flame retardant,high

mechanical strength,dimensional

stability etc. Especially it has very good heat sink,electromagnetic

shielding and solder float.

It’s

widely used for the modifier and sparker on fire for

motorcycle and mobile,power LED,sound

box, power supply module and

acoustics shielding system etc.

Note:HUADING

specially produces Metal Base Copper-Clad Laminates,and

our products have been compiled series with all complete

specifications.

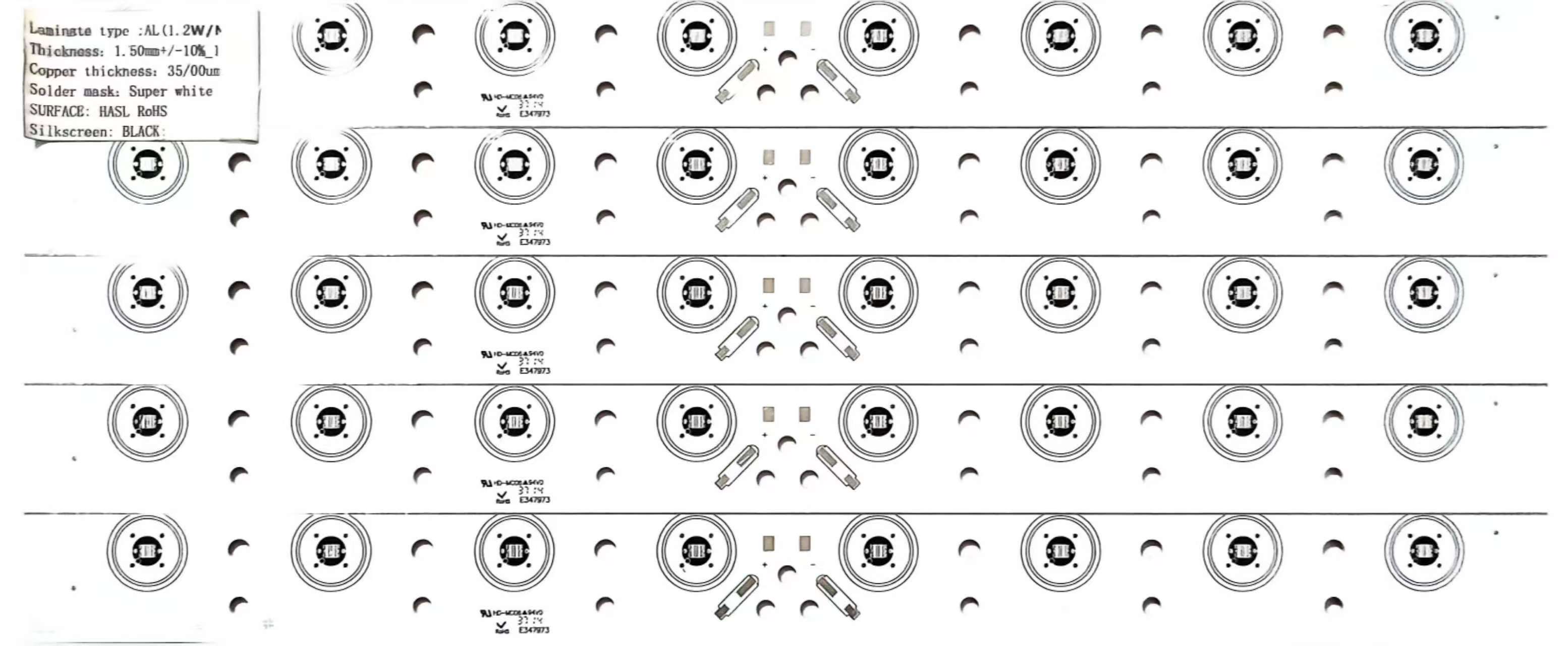

●The type and specification of

Aluminum based Laminates HDAL-01,HDAL-04-A,HDAL-05etc.and

0.8mm , 1.0mm , 1.5mm , 2.0mm , 3.0mm etc. ●

thickness of the copper:18um,35um,70um,105um,140um..

Base size: 330mm by 380mm (13〞by

15〞); 500mm ×

600mm (20〞×24〞);

380mm × 660mm

(15〞×26〞)

HD-MC04 Aluminum-based PCB Technical Data sheet

Test base :

HD-MC04 Aluminum-based PCB

Thickness of copper:35um

Dielectric layer : 120um-130um

Cu base: 1.6mm

The result of the test:

|

No |

Test item |

U. |

Assay |

|

1 |

Peel Strength |

A |

N/mm |

1.5 |

|

After thermal

stress(260℃) |

N/mm |

1.3 |

|

2 |

Blister test

After Thermal stress |

/ |

(288℃,2min)

No

Delamination,No blister |

|

3 |

Thermal

resistance |

℃/W |

0.45 |

|

4 |

Thermal-conductive Factor |

W/m·k |

2.2 |

|

5 |

Flammability(A)

|

/ |

FV-0 |

|

6 |

Surface

Resistivity |

A |

MΩ

|

3.68×107

|

|

Constant

humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.39×106

|

|

7 |

Volume

Resistivity |

A |

MΩ

|

4.2×108

|

|

Constant

humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.17×107

|

|

8 |

Dielectric

Breakdown AC(leakage 5mA) |

KV |

6 |

|

9 |

Dielectric

constant(1MHZ)(40℃,93%,96h) |

/ |

4.24 |

|

10 |

Dielectric

dissipation factor (1MHZ)(40℃,93%,96h) |

/ |

0.03 |

|

11 |

CTI |

V |

600 |

|

12 |

Operating

Breakdown (AC) |

V |

500 |

|

13 |

Glass

transition |

℃ |

125 |

|

14 |

Thickness |

um |

120 |

Method Description

1- Optical 2- Internal TO-220 test RD2018 3- Calculation

from ASTM 5470 4-Extended ASTM 5470 5-ASTM D149 6-ASTM D150

7-Internal MDSC test RD2014 8-UL 746E 9-ASTM D2861 10- CPCA

4105-2010

Note: For applications with an expected voltage over 480

Volts AC, HUADING recommends a dielectric thickness greater

than 0.003”(76um)

Note: Maximum test voltage is a function of material and

circuit design.Typical proof test not represent the maximum.

Note: Circuit design is the most important consideration

for determining safety agency compliance.

HD-MC06 Aluminum-based PCB Technical Data sheet

Test base :

HD-MC06 Aluminum-based PCB

Thickness of the copper:35um

Dielectric layer:120um-130um

Thickness of the aluminum-base: 1.6mm

The result of the test:

|

No |

Test item

|

U. |

Assay |

|

1 |

Peel strength |

A |

N/mm |

1.4 |

|

After thermal

stress(260℃)

|

N/mm |

1.2 |

|

2 |

Blister test

After Thermal stress |

/ |

(300℃,2min)

No

Delamination, No Blister |

|

3 |

Thermal

resistance |

℃/W |

0.4 |

|

4 |

Thermal-conductive Factor |

W/m·k |

2.5 |

|

5 |

Flammability(A)

|

/ |

FV-0 |

|

6 |

Surface

Resistivity |

A |

MΩ

|

3.5×107

|

|

Constant

humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.38×106

|

|

7 |

Volume

Resistivity |

A |

MΩ

|

4.3×108

|

|

Constant

humidity treatment(25℃~65℃,

RH:90%~98%,20

circulate) |

3.2×107

|

|

8 |

Dielectric

Breakdown AC(leakage 5mA)

|

KV |

6 |

|

9 |

Dielectric

constant (1MHZ)(40℃,93%,96h)

|

/ |

4.1 |

|

10 |

Dielectric

dissipation factor (1MHZ)(40℃,93%,96h)

|

/ |

0.031 |

|

11 |

CTI |

V |

600 |

|

12 |

Operating

Breakdown (AC) |

V |

500 |

|

13 |

Glass

transition |

℃ |

130 |

|

14 |

Thickness |

Um |

120 |

Method Description

1- Optical 2- Internal TO-220 test RD2018 3- Calculation

from ASTM 5470 4-Extended ASTM 5470 5-ASTM D149 6-ASTM D150

7-Internal MDSC test RD2014 8-UL 746E 9-ASTM D2861 10- CPCA

4105-2010

Note: For applications with an expected voltage over 480

Volts AC,HUADING recommends a dielectric thickness greater

than 0.003”(76um)

Note: Maximum test voltage is a function of material and

circuit design.Typical proof test not represent the maximum.

Note: Circuit design is the most important consideration

for determining safety agency compliance.